Starmatic Solution

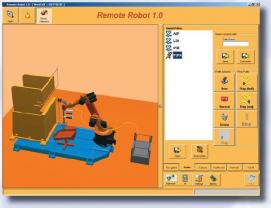

Remote Robot 1.0

The driving hardware consists of two heavy duty, hall sensor proportional joysticks, each of them with three axis control and dual button switches.

A touch screen monitor allows quick access to the software functions, like device configuration, mode selection and positioning of the virtual camera in the simulated environment.

It is also possible to drive and monitor the robot digital I/O in order to interact within the surrounding environment (e.g. picking an object with the gripper, having an immediate feedback on the applied force).

Virtual Safe Control

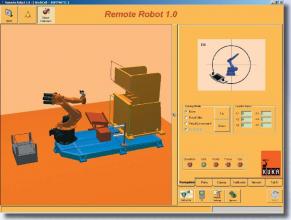

The virtual environment displayed on the Remote Robot console allows to freely choose the point of view, enabling the operator to look at the robot with the best preferred perspective, otherwise unconfortable or even unaccessible.

A number of networked real time video cameras are also directly accessible from the Remote Robot graphical interface, together with a special driving mode that enables the operator to move the robot with respect of the current camera camera perspective or using the current simulation environment point of view.

Path recording, storage and replay (forward or reverse) are also available either by exact acquisition and reproduction of a series of points in the space, or provided via automatic path generation.

Given a start point for a path (even with some pass-through points and an end point) the kinematic engine of the Remote Robot automatically computes a safe path to drive the robot, through all of the given points, avoiding collisions with surrounding obstacles.

Gripper status (active or Inactive) is included in path recording, allowing manual teaching for object pick-up, together with motions and back to replay.

Remote Robot can also act as a visive remote monitoring tool for a working cell that runs with standard robot programs.

In order to operate Remote Robot needs only a dedicated LAN (100Mb) connection with the robot controller; virtually any type of robot can be supported and users can build their own environment using 3D models or parametric objects.

Main Features

- Three-dimensional virtual environment model for real-time collision check

- Multiple driving modes: axis, cartesian world, cartesian tool, cartesian frame

- Automatic path calculation

- Path storage for future playback in forward/reverse mode

- Intuitive motion thanks to the view-relative motion mode

- Multiple camera view for real environment monitoring

- Visive monitoring of a remote working cell

- Handling gripper supported

Remote Robot desktop console

Remote Robot 1.0 is equipped with a personal computer featuring:

Operating System Windows 2000 Pro or XP Pro

CPU Pentium 4 2.8 GHz

SVGA NVidia GE-Force 4 128MB or equivalent

RAM DDRAM 512 Mbytes

Hard Disk 20 Gbytes

Dual network interface cards Intel/3Com T100 or equivalent

Monitor 15" TFT with resistive touch screen