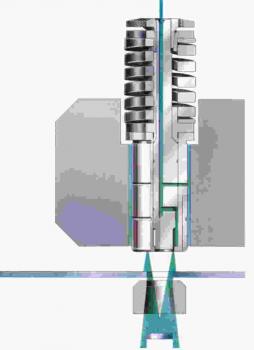

| Airblow Tooling |

|

Lubrication in all critical areas |

"Ultimate Punching Environment" The Airblow system creates a punching environment which, dramatically reduces the risk of tool jams, slug problems, sheet pulls and general tool maintenance.

The Airblow system accurately injects a combination of lubrication/cooling oil and compressed air (oil mist) into the Airblow tool. The oil mist is distributed through the punch body, into the guide, out into the turret bore and down through the work piece and die. This process ensures that the tooling and the turret bore are lubricated in all of the essential and critical areas, increasing tool life typically by three times. The Airblow system is effective in reducing "cold welding" or "micro-fusing". This phenomenon causes poor component quality and rapid tool wear. Any fine needles or slugs are ejected harmlessly through the die after punching by the Airblow system. The system can focus on the most critical areas and tools, where it will have maximum effect. |