TE195

- Advanced microprocessor control unit for suspended guns

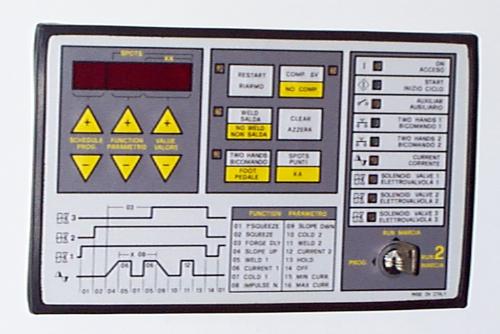

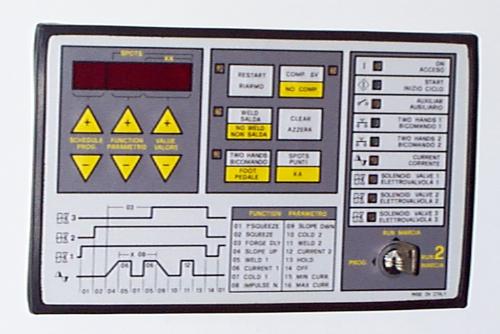

WELDING CONTROL UNIT TE 195

The TE 195 is a microprocessor welding control unit for suspended resistance welding guns. This control unit includes specific functions to be used when working with suspended welding guns, such as the double stroke control, and a function checking the efficiency of the safety devices which can be installed on the machine. It is possible to program and to store up to 15 different welding programs. All the programs can be recalled directly from the keyboard and program number 2 can be recalled from an external device. The control unit can be programmed for working under two different operating modes: standard one and and constant current. Each program can assume all the configurations included between the simplest 4 times cycle, up to the most complex one, which can include the slopes, the pulses and the post-heating. Other available functions are the welding current stepper function and, under standard operating mode, the compensation of the variation of the mains voltage and the compensation of the minimum current.

MAIN FEATURES

* under constant current operating mode

MAIN FEATURES

- 15 welding programs.

- 15 programmable parameters for each program.

- Control of 2 solenoid valves 24 Vdc 7,2 W Max with protected output against short circuit: electrode closing valve and double stroke valve.

- Double operating mode: standard and constant current.

- Measure and display of the welding current in kA.

- Measure and display of the max. welding current conduction angle.

- Adjustment of the welding time in half-periods.

- Welding current limits for each program under standard operating mode.

- Current conduction angle limits under constant current operating mode.

- Counter of the performed welds.

- Output of endcycle with relay, which can also be selected as an interlock.

- Output signal for out-of-limits spots with relay.

- Automatic compensation against voltage drops under standard operating mode.

- Minimum current compensation function under standard operating mode.

- Stepper function against electrodes wear.

- Restart key and outputs enabling under Watch-dog control.

- Serial communication by means of insulated RS-232 interface (optional).

- Removable key for programming or for run.

- Integrated ammeter with four different capacities to select (18,36,45,90 kA).

- Key to select single button control or two hands control.

- Possibility to eliminate the autoretain of the start signal during the welding process.

- Self-adjustment to the network frequency 50/60 Hz.

PROGRAMMABLE PARAMETERS

| PARAMETER | RANGE |

| 1° SQUEEZE | 00 - 99 cycles |

| SQUEEZE | 01 - 99 cycles |

| SLOPE UP | 00 - 29 cycles |

| WELD TIME 1 | 00.5 - 99.5 cycles |

| CURRENT 1 | 10 - 99 % 2.0 - 90.0 kA * |

| COLD TIME 1 | 00 - 50 cycles |

| IMPULSE N. | 00 - 09 |

| SLOPE DOWN | 00 - 29 cycles |

| COLD TIME 2 | 00 - 50 cycles |

| WELD TIME 2 | 00.0 - 99.5 cycles |

| CURRENT 2 | 10 - 99 % 2.0 - 90.0 kA * |

| HOLD TIME | 01 - 99 cycles |

| OFF TIME | 00 - 98 cycles |

| MIN. CURR. | 0 - 90 kA 0 - 180° * |

| MAX. CURR. | 0 - 90 kA 0 - 180° * |

* under constant current operating mode

Specifications subject to change without notice.