Special Applications & Solutions

|

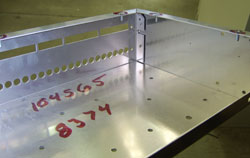

HARDIGG BOTTOM FEED SHUTTLE NUT TO ACCESS TRICKY PART

Description of Application: Several M6 nuts being inserted into formed aluminum parts. Customer Requirement: The ability to automatically insert all M6 nuts into every formed part utilizing only one tooling set to eliminate tooling changeover. Haeger Solution: Haeger’s Custom Tooling department designed & manufactured a special bottom feed shuttle nut mechanism that allows access to all nut positions into formed parts which have many bends. The customer was able to increase profit and throughput by utilizing Haeger’s special tooling capabilities, which decreased tooling set up time and increased the number of completed parts per hour. |

|

|

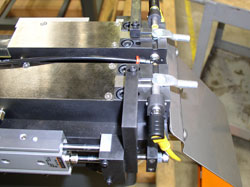

J-FRAME BLIND NUT AUTO FEED INTO FLANGED PART

Description of Application: Blind nuts being inserted into flanged part. Customer Requirement: The ability to auto feed blind nuts automatically into a shallow formed flanged part. Haeger Solution: Haeger’s Custom Tooling department designed & manufactured a special J-frame automatic tooling set that provides the customer access to every blind nut under the flange of the their part.

Customer Benefit: The customer was able to quickly insert all the blind nuts into their part automatically with only one part handling. |

|

|

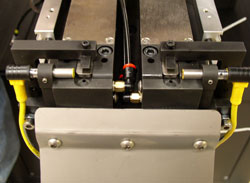

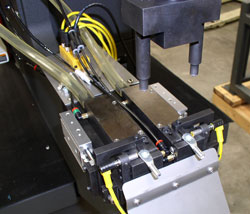

SHULTE DUAL ABFT (Automatic Bottom Feed Tooling) FOR BATTERY TERMINALS

Description of Application: Nuts being inserted into battery terminals. Customer Requirement: The ability to dual feed two nuts simultaneously into battery terminals, with a part ejection feature. Haeger Solution: Haeger’s Custom Tooling department designed & manufactured a special dual automatic lower tooling that holds two part assemblies in place for insertion. After insertion, the assemblies are ejected automatically, while the operator prepares to insert terminals for the next insertion.

Customer Benefit: The Customer was able to increase their completed part assembly time by more than 50%. |

|